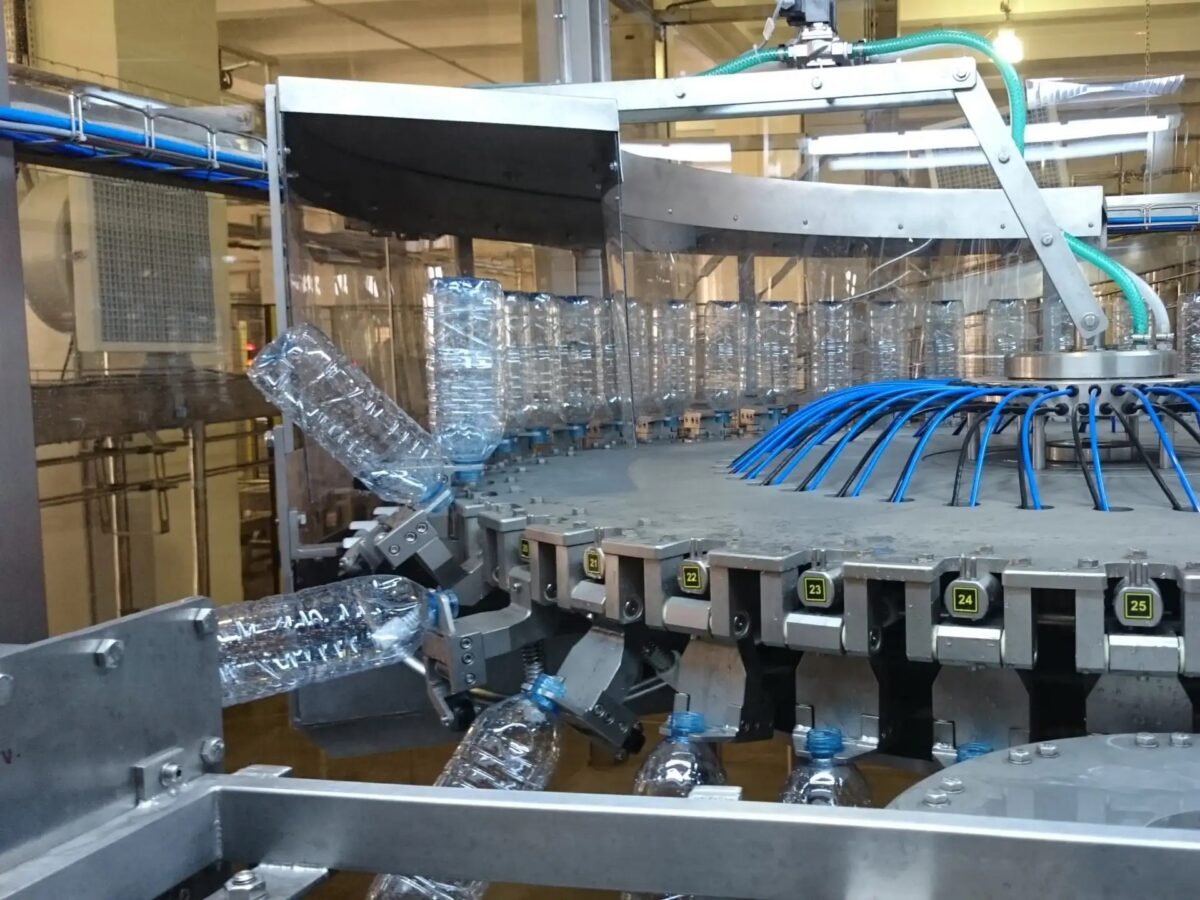

Bottle capping machines are used for capping filled bottles. They are availabe in designs for crowns, screw metal and plastic caps, bugels and other special types of closures. The machines for cans contain a seaming unit.

The unit is usually a part of the filling block with capacity according to the filling machine. An execution and a number of closing heads vary according to the capacity. Semi-automatic machines have a pneumtical one-head unit with manual bottle inserting. Mid-range fillers are usually equipped with pneumatical or mechanical (a universal version for both crowns and screw caps is available) one-head unit with step-by-step feeding star. The highest range offers continuous mechanical multi-position units.

The closing unit is usually supplied with a cap tray, a cap orientation and a feed rail.