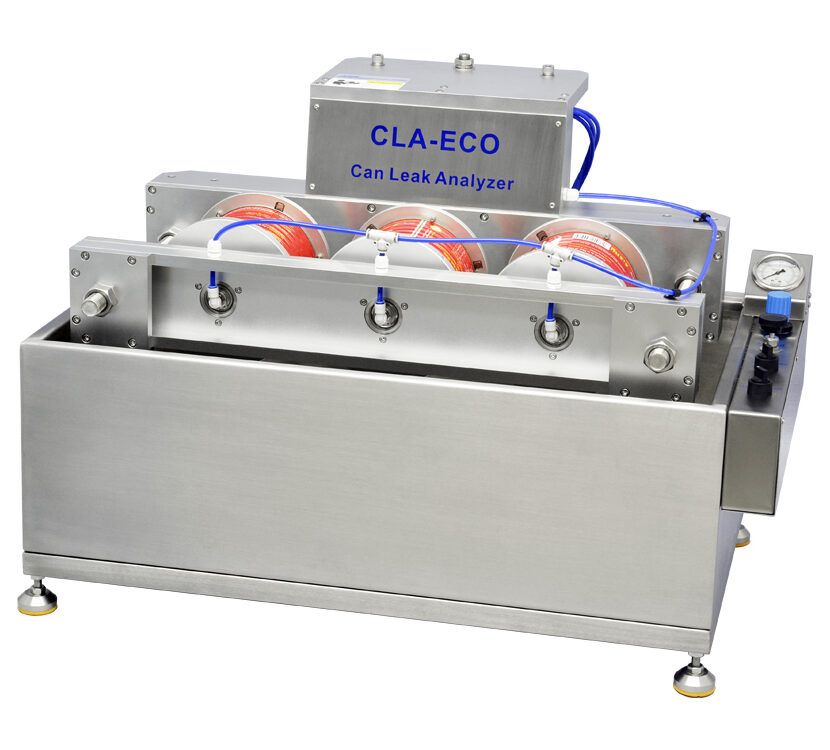

CLA-ECO Can Leak Analyzer is specifically designed for analyzing the secure seal ability of the empty 3-pieces tinplate cans. Water bath design with free rotating can holders allows a 360° observation on the can body (especially welding position) for air bubbles. It also ensures no defect spot can be missed and provides reliable test result.

Features:

- Pneumatic design which allows the tester be free from electricity

- Stainless steel water bath

- Semi-automated immersion

- Multiple testing positions (please consult AT2E for different position request)

- Applicable for most sizes of 3-pcs can

- Easy installation of samples