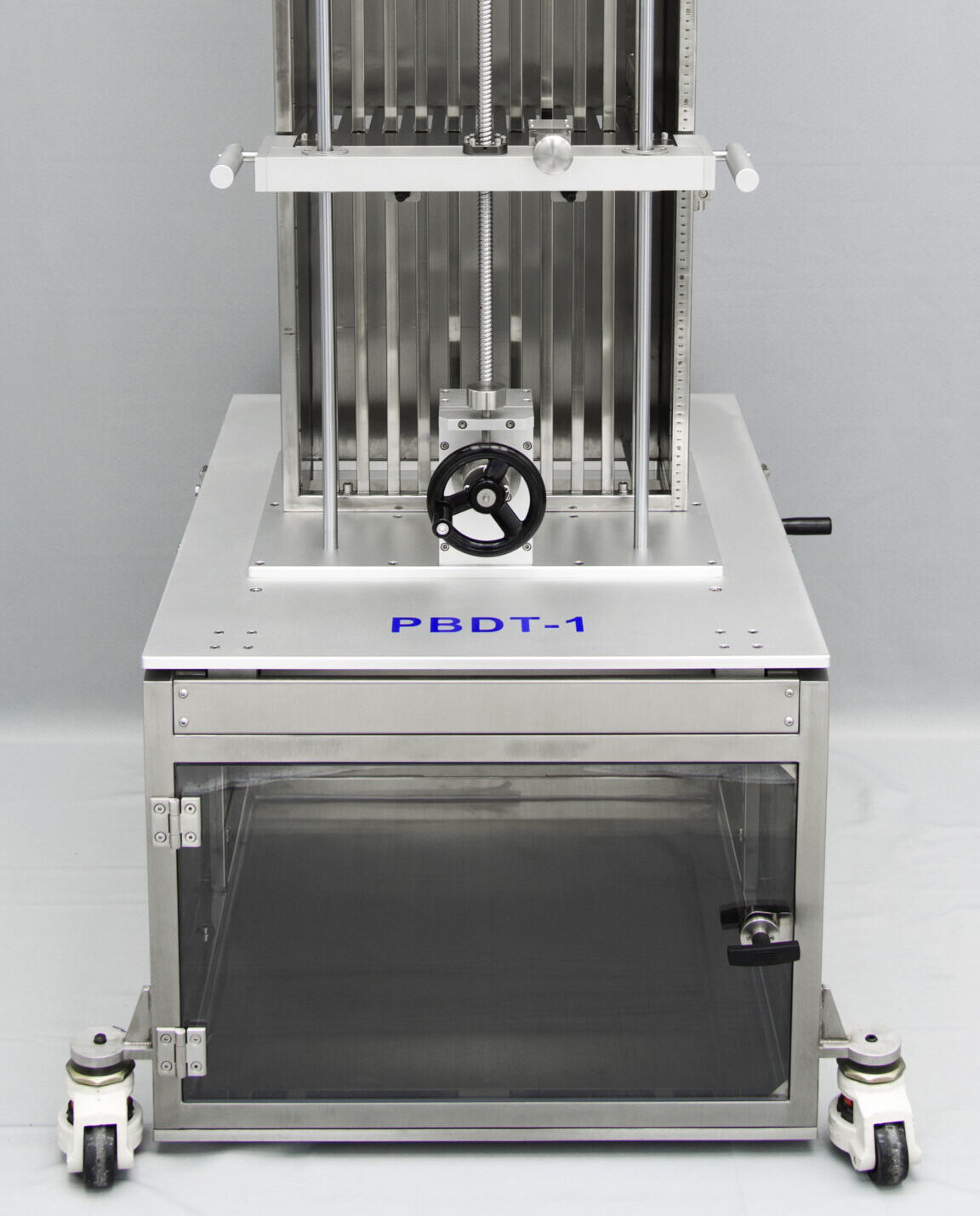

Designed To Be Installed Under Capping Head – Screw Cap -Pilfer Proof – Secure Child. Our dynamometers include a special mechanical design permitting to avoid all influence from non-coaxial efforts. Also built-in a high speed electronic reading of measurements.

Technical specifications:

- Separate digital display

- Measures compression (top load)

- Measuring range: 000.0 to 500.0 Kgf

- 2 Measuring modes (continue, peak)

- Units: Kgf / lbf / N

- Accuracy: 0.5 % of full scale

- Loading by USB (PC)

- Reversible display)

- Delivered with COFRAC certificate

- Transport case

- 110 / 230 V – 50/60 Hz

Using:

- Ready to be installed on line after filling machine

- Enables to control capping heads in real conditions (speed and top load)

- No more dismantling!!

- Interchangeable formats