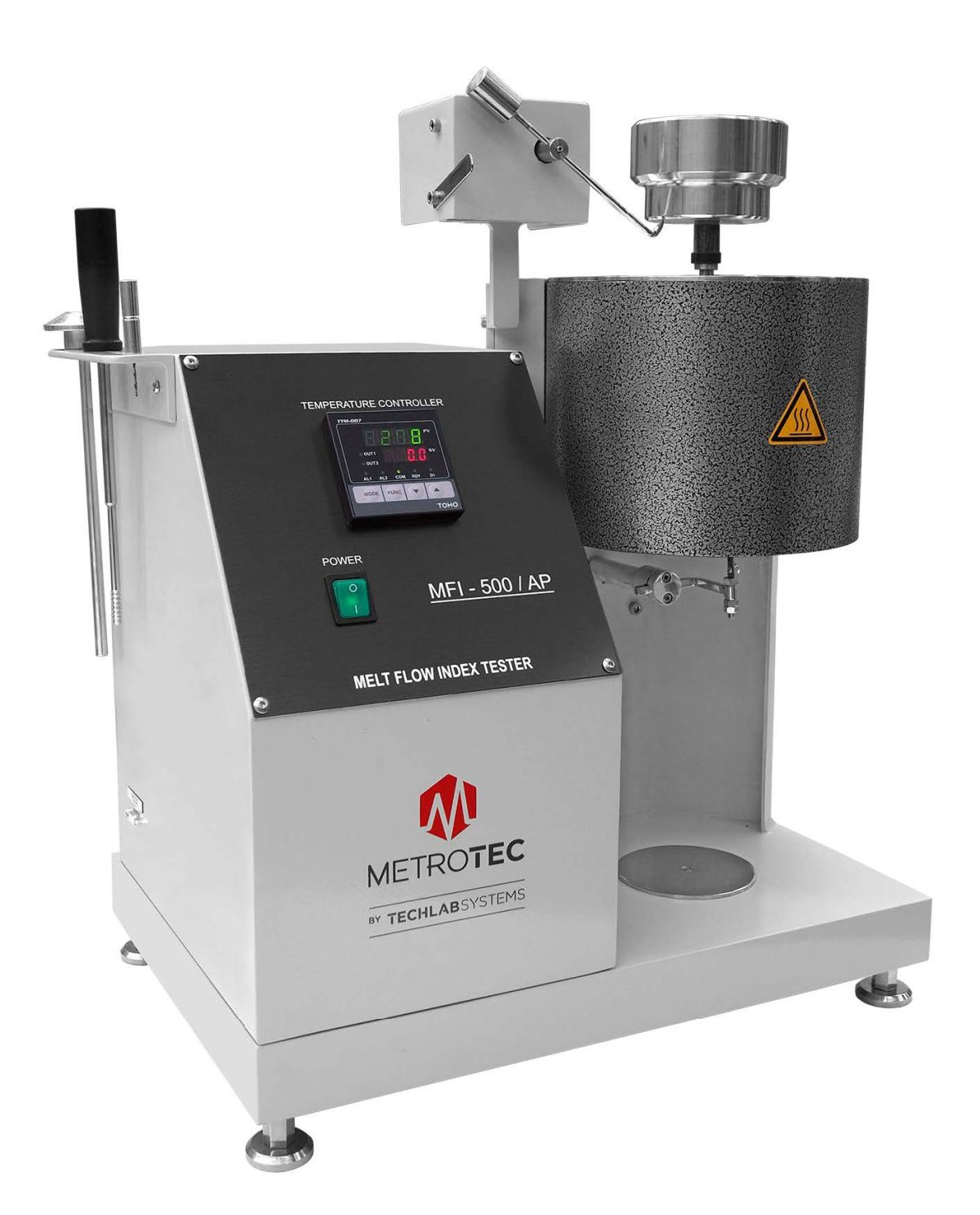

MFI-100 is designed specifically for use in the Quality Control Department as a quick and easy Melt Flow Indexer for thermoplastic materials according to the “A” Method of the international standards of MFI, ASTM D1238 – ISO 1133 in both Procedure A (Gravimetric).

- GRAVIMETRIC method

- Low cost

- Automatic Sample Cutting

- Robust design with high rigidity

- PID temperature controller (maintain +/- 0.1 ° C)

- Time programmer and number of cutting cycles

- Equipment ready to work with corrosive materials such as PVC

For Manual testing (Method A – Gravimetric)

The standard equipment includes all standard work-cleaning tools, piston and nozzle.

- Temperature Controller with a range up to +325 ºC (*) with a resolution of 0.1ºC

- Digital Stopwatch: with a range of up to 9999 seconds with audible alarm.

- Automatic sample cutting

- Complete set of 7 chromed and polished weights: 1.2 Kg – 2.16 Kg – 3.8 Kg – 5 Kg – 5 kG – 6.6 Y 10 Kg

- The weight of 21.6 kg is a combination of the weights of 5 kg, 6.6 kg and 10 kg

User manual and warranty letter

Melt Flow Indexer MFI-100 complete and ready to workAccessories included in the standard supply: Tungsten Carbide Nozzle, Piston, pellet picker, wrench, sample insert rod in the heater drum, material feeder, funnel, heater cleaner, scissors, nozzle cleaner .