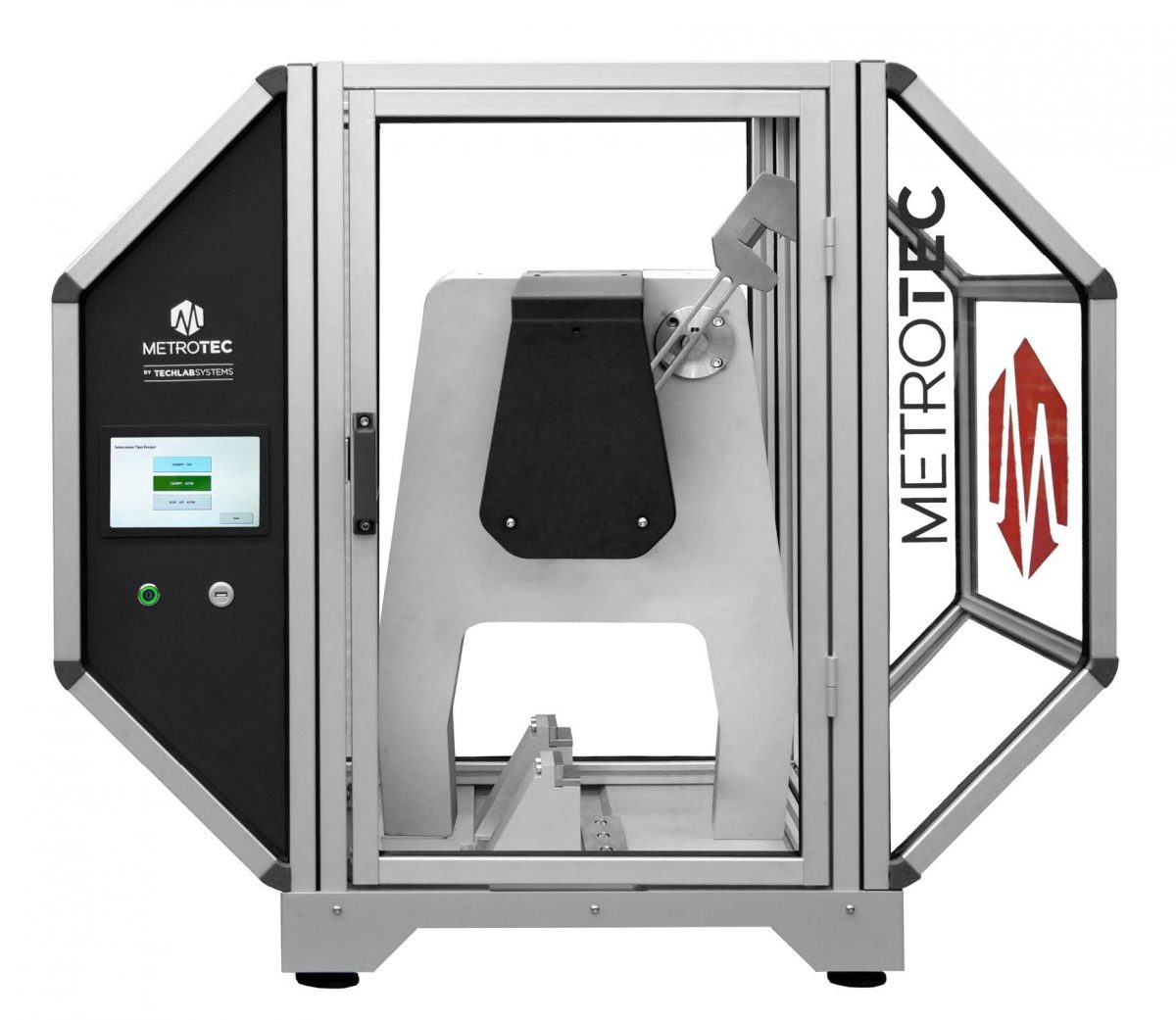

Equipment designed to perform standardized notches on samples, which are then subjected to monoaxial impact resistance tests, according to the CHARPY and IZOD procedures.

Characteristics:

- – blades * at a fixed angle of 45º ± 1º:

1 according to ASTM D 256 with radius of 0.25 mm ± 0.01mm

1 according to ISO 179/180 to choose between:

. Type A with 0.25 mm ± 0.05 mm radius

. Type B * with radius of 1 mm ± 0.05 mm

. Type C with radius of 0.1 mm ± 0.02 mm - Analog micrometer with depths of 0-25 mm with a resolution of 0.01 mm

- With variable speed to cover a wide range of materials: between 0 and 225 r.p.m.

- With protective safety screen

Notching Machine MNC-10 with safety protection lock

- If no other type of blade is indicated, the standard supply includes 1 ISO 180 Type B Blade

· Cutting blades made of high-speed heat-treated steel - 2 blades of the same ASTM or ISO standard can be supplied, or one of each standard, depending on the chosen configuration.