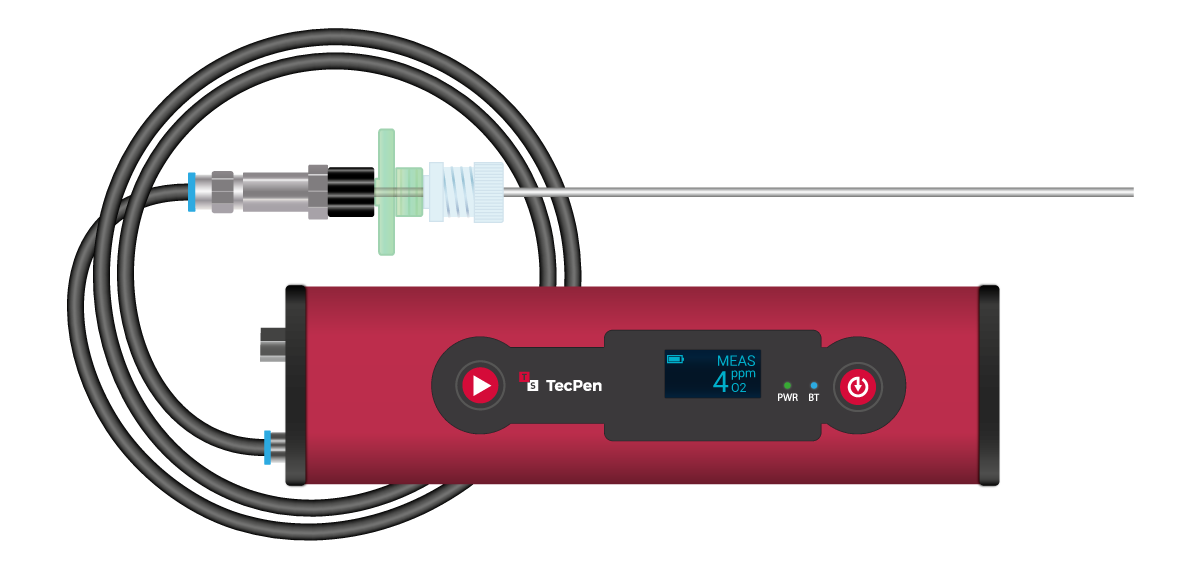

Non-invasive determination of residual oxygen

- No waste of food

- Reduction of plastic packaging waste

- Cost reduction

- Highest quality assurance for the customer

- Easy handling

- Can be used everywhere

- Time and date stamp for each individual measurement

- Effortless traceability of the measurements through ready-made recipes

- Integrated temperature sensor

Application

- Incoming inspection at the acceptance of packed food in trade

- Random quality control during the packaging process

- Quality assurance in the production of insolating glas Noninvasive determination of residual oxygen in bioreactors