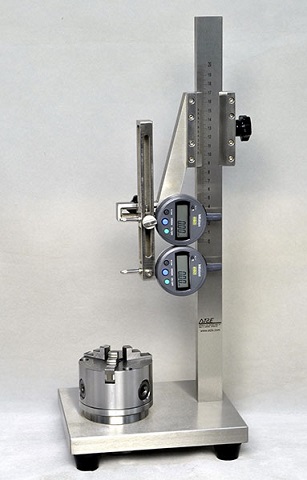

The SSA-PLC-12 Secure Seal Analyzer (12 Positions) is a special instrument developed by AT2E for control of the secure seal performance of caps on preforms.

Attributes:

- Muilt-position design, more convenient and efficient.

- PLC control ensures the high accuracy and reliability.

- Stainless steel frame, more safe and durable.

- Flexible position selection, each position can be controlled separately by system, users can choose to enable the positions (from 1 to 12) according to their needs.

- Linear pressurizing, able to set up to 4 pressurization steps, and hold the pressure according to the predefined period.

- Auto pressure compensation during test process

- Special designed clamping device, enhanced the sealing performance of test.

- Anti-explosion and clear observation window, safe and easy to observe the sample status during tests.