Tests on:

- Bottles: Glass or PET and Preforms

- Caps: Aluminum, other metal, plastic

- Cans: Aluminum, others

- Pots: caps, film, blisters etc.

Techotrix AT2E secure seal tester is a versatile and highly reliable piece of equipment designed to meet the stringent quality control and packaging integrity needs of various industries. It serves as an essential tool for ensuring the integrity of your products, whether you operate in the food and beverage, pharmaceutical, cosmetics, or other sectors requiring secure packaging.

Key features include:

Tests on:

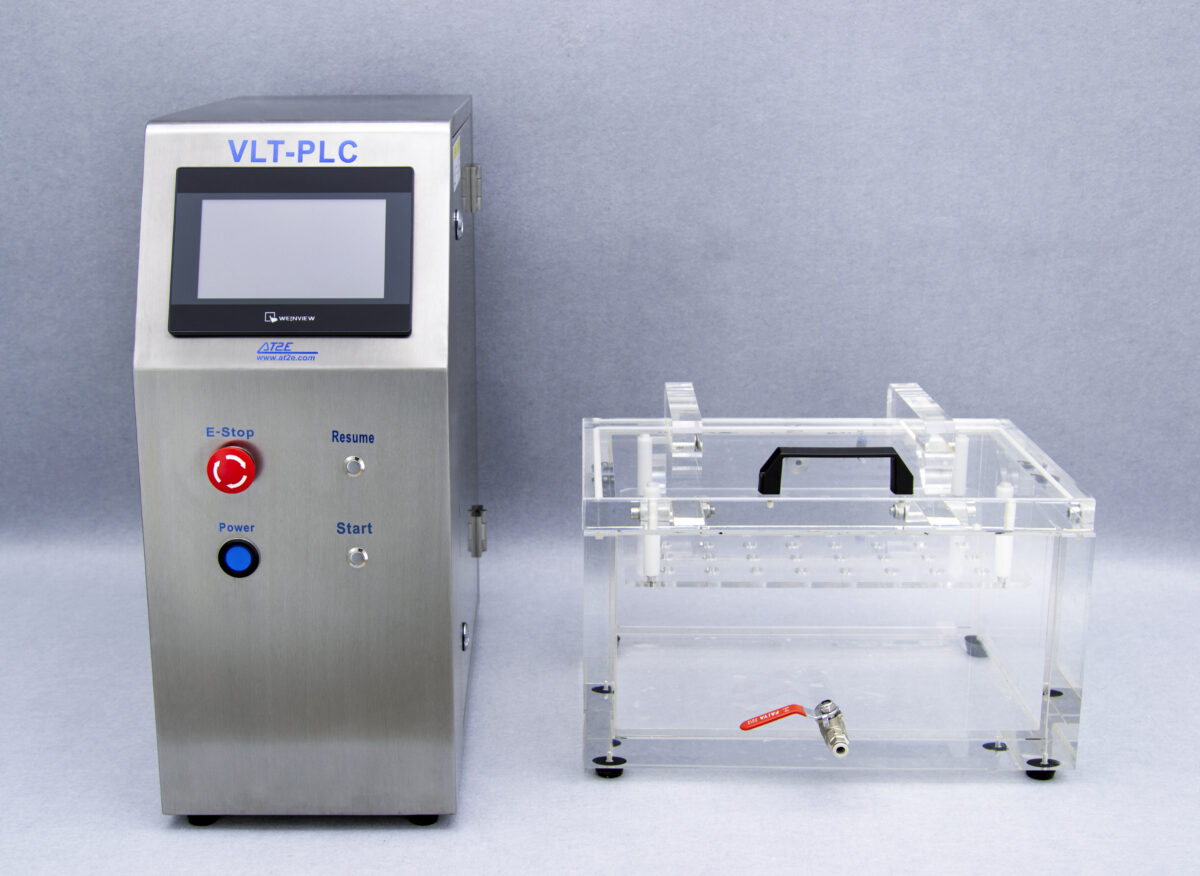

VLT-ST is equipped with a touching screen. It‘s visual and easy to operate. Adjustable vacuum and holding time stage setting, meets different test requests of various products.

Tests on:

Leak detection by setting vacuum with or without step.

Tests on:

Used for testing the air-tightness of the crown cap. Stainless steel design ensures the durability of the tester during test. Cap the crown cap on the neck of the bottle mold, plunge the cap in the water tank, then increase the internal pressure and observe if there are air bubbles coming out, so that to test the air tightness of the caps. Widely used in breweries, beverages and caps manufacturing industries.

AT2E CTLT Cosmetic Tube Leak Tester is for testing the secure seal performance of the cosmetic tube products. With the special design, use a seal rubber to form a temporary sealed condition from the tube bottom, then apply a certain pressure level to test the secure seal ability of the tube. Controlled by touching display, it’s visual and easy to operate. Adjustable pressure and holding time stage setting meets different test requests of various products. Its stainless-steel frame and enclosed test chamber design makes it resistant of any explosion during the test and ensures the safety of the operator.

Its easy operation provides a simple and convenient solution for customers.

AT2E SSA-ECO secure seal analyzer is for testing the secure seal performance of products. With AT2E patent needle, it makes the installation and piercing very quick and easy in any medium. By vacuum technology and special design, the needle uses a function of self-holding on the tested products. However, the SSA-ECO can be compatible with using the needle of the classic Secure Seal Tester (typical screwed needle). It’s stainless steel design makes it resistant of any explosion during the test and ensures the safety of the operator.

AT2E SSA-D secure seal analyzer is for testing the secure seal performance of products. With AT2E patent needle, it makes the installation and piercing very quick and easy in any medium. By vacuum technology and special design, the needle uses a function of self-holding on the tested products. However, the SSA-D can be compatible with using the needle of the classic Secure Seal Tester (typical screwed needle). It’s stainless steel design makes it resistant of any explosion during the test and ensures the safety of the operator. SSA-D is equipped with a touching screen. It’s visual and easy to operate. Adjustable pressure and holding time stage setting meets different test requests of various products.

AT2E SSA-AUTO Secure Seal Tester is for testing the secure seal performance on products. SSA-Auto is an automated machine with automated piercing process and pressurizing process. Integrating AT2E patent needle, it allows automated installation. By vacuum technology and special design, the needle uses a function of self-holding on the tested products. Stainless steel design makes it resistant to any explosion during the test and ensures the operator’s safety. SSA-AUTO equipped with a touch screen. Visual and easy to operate. Adjustable pressure, pressurizing rate and holding time stage (up to 4 stages) setting meets different test requests and standard of various products.

AT2E SSA-AUTO F Secure Seal Analyzer is for testing the secure seal performance on products. It’s an automated machine with automated piercing process and pressurizing process. Integrating AT2E patent needle, it allows automated installation. By vacuum technology and special design, the needle uses a function of self-holding on the tested products. Stainless steel design makes it resistant to any explosion during the test and ensures the operator’s safety.

SSA-AUTO F is equipped with a touching screen. Visual and easy to operate. Adjustable pressure, pressurizing rate and holding time stage (up to 4 stages) setting meets different test requests and standard of various products.