The Test Machines are controlled in closed loop by a high performance PC Touch Screen, which allows to operate Automatically in the realization of the tests, by means of the Software of Tests of Materials modular “METROTEST”. We have a wide range of test accessories (Grips, Extensometers, Thermal Test Chambers, Bending Test Devices, Special Tools Tests Devices).

Thermal Test Chambers CTE-1 prepared for coupling to the Universal Testing Machines

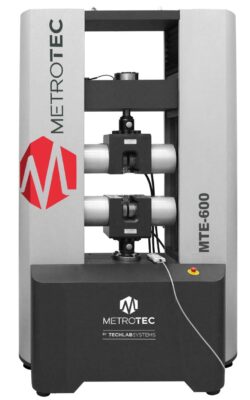

Tensile Testing Machines – Tensile Meters – Materials Mechanical Testing Machines – Universal Machines Mechanical Testing

- Fully computerized: The control and measurement system with specific electronic board used for testing machines, performing the zero tare, and adding a setting which is very reliable.

- It has a database manager for the test results which stores according to a standard format which facilitates analysis and transfer to other programs.

- Compliance with test requirements for all types of materials with all international testing standards.

- With a wide range of functions in the graphics, you can make color changes of the curves, magnifications (zoom), reductions, selfscaling of the curves (which facilitates and shortens the time of a test with a new one Material), displacement of the curves in the axis of deformations, designate standard curve, association of labels to each graph, indication of values digitally on the screen and printing all kinds of test curves.

- Modular design facilitates software upgrades in the future, etc.

Configuration:

- 1 750 kN Tensile / Compression Load Cell

- 1 METROTEST Advanced Testing Software – Multilingual (Spanish – English – French and German)

- 1 Pack of Statistics: Bar Graphs – Gaussian Bells and Comparison of References

- 1 All-in-One PC Touch Screen with 22 “Monitor Panoramic

- 1 ENAC Calibration Certificate (equivalent to NIST Certificates – UKAS – DKD …)