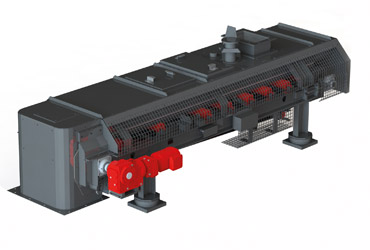

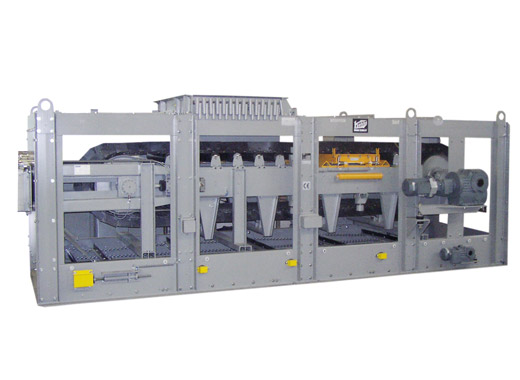

The classical area of application is in the mid to high range of capacity for continuous dosing of fine-grained to coarse-grained bulk materials. Depending on the nature of the bulk material the weigh feeder E-DBW-A is of “open” design available with covered conveying channel. KUKLA weigh feeders are built on a solid steel frame in order to guarantee the stability required for high-precision measuring. Each KUKLA standard scale is provided with a test weight device, which permits an easy and quick check of weighing accuracy within a few minutes. An integrated weight-loaded belt steering and tensioning device ensures high accuracy and high reliability.

Significant Benefits

- Test weight for an easy and quick check of the weighing accuracy

- Integrated belt steering and tensioning device

- Versatile in use

- Minimal maintenance works

Requirement

- Stable vibration-free subconstruction