AT2E’s AF 1 Automated Filler is designed as a quick water filling device of bottles. It’s mainly used to improve the efficiency for some tests which require a filled bottle, such as stress crack test, secure seal test, burst test and so on… It can fill 6 bottles in 1 time at predefined volume with high accuracy.

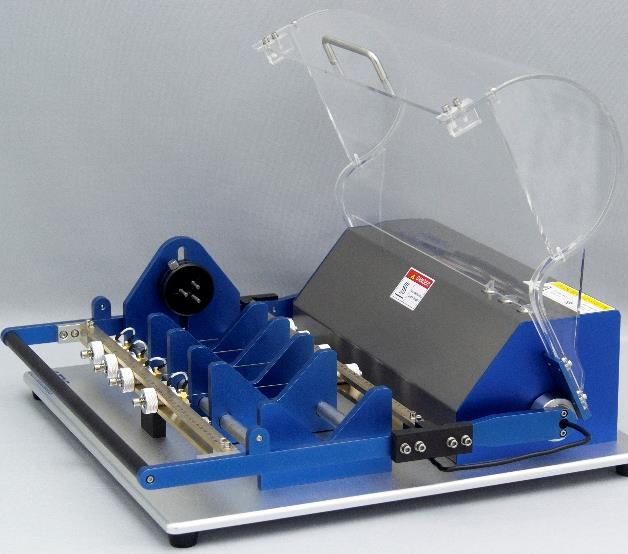

The HWBC-1 Hot Wire Bottle Cutter offers an easy and cost saving way for cutting containers for section weight analysis. A clean section without deformation will be obtained by a quick cutting of bottles through heated hot wires. A precision and repeatable cutting task is easy to achieve and it’s necessary for a proper analysis.With HWBC-1, a PET bottle could be cut up to 5 predetermined sections, each section will be checked to ensure that it conforms to the exact weight assigned.

Attributes:

- Durable design & Easy to operate & Excellent repeatability

- Bottle cut with accuracy up to 5 sections cut

- Cutting up to 2 L bottle

- Universal finish support, compatible for the bottle finish diameters from 17 to 40 mm

- Adjustable supports for bottles during the cutting process

- Graduated rulers allow accurate positioning of wires

- Safety cover design which exhausts gases out of face of the operator (optional)

- Rapid warming the wires

- Dual heating mode saves energy and extends the life of wires

- Adjustable heating power allows operator to select the correct power according to different bottle and prolong the life time of the wire.